Insulated terminals have a major function to3s perform in the matter of SAFELY AND WELL CONNECTING Wisres. Those are bits that cover the ends of wires so that electricity doesn’t jump out or get in trouble. These terminals, which are made of metal and plastic, help keep things tidy, prevent wires from being harmed and put a stop to shocks or short circuits. Whether you are repairing something at home, fixing a car or have an assembly line of machine that needs to be wired together, insulating terminals make sure wires stay put and know they will remain safe. GEN’s insulated terminals are crafted with precision to meet the requirements of various applications, ensuring everything is in working order without hassle.

It can be difficult to find a decent source for purchasing insulated terminals in bulk. Frequently, people search for sellers who produce things that won’t smash or harm us. At GEN, our emphasis is on providing customers with terminals that are durable and work correctly the first time to keep your forklifts moving. We’re confident that if you’re buying in bulk, both quality and price matter; our factory produces connectors with metal cores as strong as your relationship but wrapped in tough insulation. This prevents wires from chafing or being sliced. Then, there’s the fact that we stock so many different sizes and types, because no two projects are the same and therefore no two terminals will be interchangeable. Tiny terminals are, for instance., required for small home wiring jobs; the heavy duty kind is used in large machinery. We hear what customers want and we make sure our products deliver. Sometimes that’s all that matters to companies who don’t give a crap, however I figure better to have something that works well every time. In our experience GEN terminals ultimately cost you fewer repairs and lets machines remain running for longer. We also ship fast, because we know time is money. Therefore, GEN as one of the Schneide dealers and exporter has those all you need products from Schneider brand and will give youp good prices. That’s why so many people return to us again and again. We don’t just sell terminals; we help people become comfortable and confident with electrical. For example, you can explore our Metal Components which complement our insulated terminals perfectly.

Why are insulated connectors so crucial for wiring safely and effectively? Picture wires touching each other with no insulation. Sparks could fly, or a short circuit might occur and fires or damage to the locomotive or attached cars could result. Insulated terminals prevent that by shielding the metal parts where wires are joined. This plastic or rubber coat is what contains electricity and prevents it spreading to things that could catch on fire or people who could get a shock. But safety isn’t all. Insulated terminals also help ease of wiring work. Cables with good terminals fit snugly into connectors or devices, so the connections don’t rattle loose — or break. This is the difference between machines and operations running better and without surprise stops. GEN’s terminals are also anti-corrosion, so they’ll still work whether it’s scorching hot or pouring rain. Cars and factories have spots where wires are exposed to dirt, water or vibration, for example. Bad insulated terminals and your connections could deteriorate in a hurry. When you use terminating GEN insulated terminals the wire stay snug and guarded, even when times are tough. Also, it is a time saver to use insulated terminals. Now terminals clip or screw on instead of wires twisted together or taped, providing a cleaner and faster job. This kind of thing saves money and makes repairs easier when it all goes tits up later. We frequently hear from our customers how using GEN terminals saved them from trouble and allowed them to keep their projects on schedule. Insulated terminals, then, are not tiny parts; they are crucial elements to ensuring that wiring is safe, organized and working for you everyday. For specific wiring projects, our Wiring Harness solutions provide perfect compatibility and performance.

Insulated terminals are tiny electrical parts that securely connect wires together in electrical projects. They are coated with a plastic or rubber layer that prevents electricity from leaping out and shocking you, or shorting out. Insulated terminals provide us with a lot of convenience, however, people will still encounter difficulties using them. Another frequent problem is that the terminal and wire don’t fit together well. The connection may be loose if the wire is too thick or too thin to fit for the terminal. This can make the wire not stay in, or the electricity stop flowing as much. To avoid that it is critical to verify the size of the wire and of course, the terminal before crossing this two. GEN offers insulated terminals in a variety of sizes, so you can easily find the appropriate size for your wire.

Another issue is poor crimping. Crimping is the act of squeezing the terminal against the wire. If this is not properly done, the joint may be loose or weak. This can create sparks or even fires. To avoid this, make sure you have the proper tools and press down hard when attaching it to the terminal. GEN has got terminals that are compatible with common crimp tool which would be more easy and safe for the job. Wire stripping isn’t properly done occasionally. Stripping simply refers to taking off the coating that covers the wire end. If you strip too much or too little, the terminal may not grip the wire correctly. At all times, ensure that you strip the appropriate amount of wire as suggested by your terminal’s material instructions.

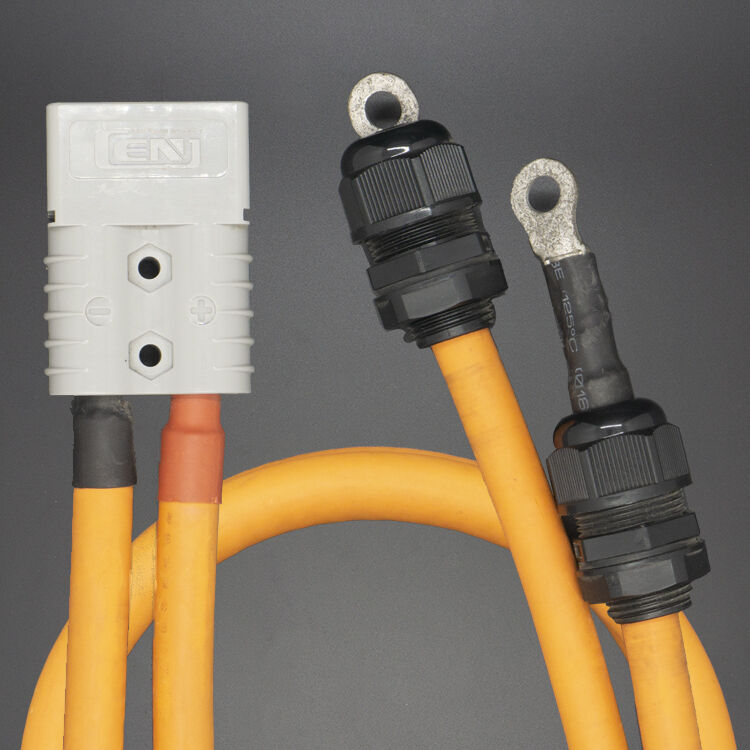

Factories and large machines have electrical work that must have parts that are very strong and safe. Insulated terminals placed in these kinds of spots need to be able to carry a lot of power and sometimes contend with harsh conditions like heat, moisture and vibration. Not all insulated terminals are created equal, so it is important to choose the right type. For commercial application of these terminals, the thick insulation types are recommended since they provide a very good resistance to electricity and hazards emanating from outside sources. GEN produces these insulated terminals with a robust plastic cover which can tolerate high temperatures and rugged use. That means they won’t easily melt or break, even from harder-to-reach areas. For high power needs, consider our SE 350A terminals designed for industrial strength and durability.

Another good industry type is terminal with copper or other good conductive metal parts. These metals allow electricity to flow with little resistance and minimize energy loss. GEN’s terminals were made out of a high-grade metal that lasted for years and performed well in machines. Some industrial terminals also come in specialized shapes, such as rings, spades or forks. These shapes are easier to connect with strong bolts or screws more common in big machines. The right shape is important, depending on what the machine requires. GEN comes in many configurations so workers can fit their tools and machines the best that they can.

Copyright © Shenzhen Green Power Technology Co., Ltd. All Rights Reserved