Wire harnesses are critical components in a wide range of machines and equipment. That means assembling bundles and bundles of wires in a way that is neat and safe, allowing electricity or signals to travel unimpeded. Machines such as cars, computers and home appliances probably wouldn’t work well or might even be unsafe without a good wire harness. Creating wire harnesses requires skill and care; the wires must be the appropriate length, joined properly and protected from damage. At GEN, we understand how essential that is because every wire harness we create is crucial to ensuring your machines keep running smoothly and safely. We also offer Oem Custom Small Stamped Processing Services Brass Aluminum Copper Stainless Steel Hardware Sheet Metal Bending Stamping Parts to complement wiring solutions.

It’s not easy to choose the right ones when you want to purchase wire harness assemblies in bulk. Step 1: Consider the quality of the parts. Cheap wires or connectors may break, or stop working soon, causing potential headaches down the road. For instance, if a wire inside a car wiring harness breaks, the car can lose power or the lights will shut off. Dont absorbs; GEN always manufactures with powerful materials which last long and keep working even in tough conditions. Then, make sure the wire harnesses have been designed for what you need. Various machines require varying sizes, shapes and kinds of wire. At times, the wires must deal with heat or water. This is why it’s reasonable to inquire whether the project has been tested sufficiently to ensure that the assembly will not break. GEN is super careful testing every harness there, no surprises please. Also consider the supplier’s experience. That matters because in wire harness manufacturing, it’s not just the wires that count but also what you know to avoid errors and solve problems quickly. At GEN, we spend years and focus on a team for every little detail. If you’re making a large purchase, you want someone who can deliver your goods on time and back you up should something go wrong. That’s why we don’t just sell wire harnesses, we stand behind them. When you inspect these, you receive wire harnesses that will save money and aggravation in the future.

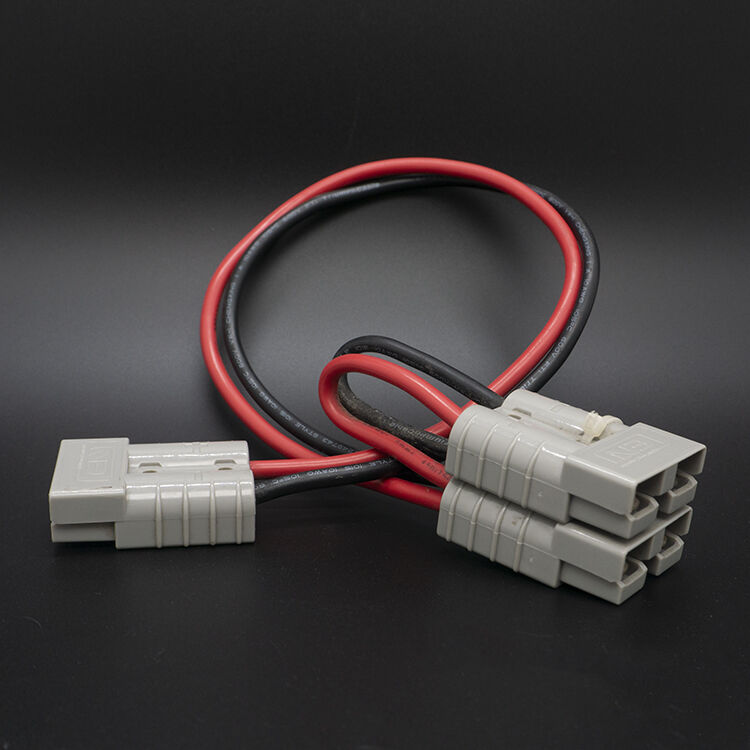

Wire harness assemblies can experience trouble, but keeping an eye out goes a long way toward preventing trouble. One common problem is connections gone bad. If wires aren’t bonded properly, or the connectors are slack, electricity might not travel as it should. This can lead to machine failure, or badly performing machines. Once a client had a huge issue when a wire rattled loose inside of the harness. It was a long time before we found it and fixed it. At GEN, we test each and every one to make sure there are no leaks in the system before it leaves our harness shop. Another problem is wire damage. Wires can be cut, bent too much or rubbed by sharp edges. This can cause the wires to break inside of the harness. To avoid this, we use protective tubes and ensure the wires have enough empty room to flex a bit without getting pinched. There are occasions where the wrong kind of wire is used. As an example, if you use a wire that isn’t heat resistant in a hot area, then it’s going to fail quickly. So, the type of wire should be chosen with an eye to where it will be used. And there can be trouble from bad design, too. When a harness is too complex or wires cross over themselves excessively, I can become difficult to install but easy to damage. GEN’s design team pays close attention to make sure that harnesses are straightforward and sturdy. And when things do go wrong, the ability to diagnose and correct issues quickly is an enormous time-saver. We always taught our clients to look for signs like flickering lights or banging sounds, and to start with the harness.” By staying ahead of these problems machines will last longer and users will experience less frustration. That’s what GEN is most concerned with. In addition, we provide a variety of 50A Andersons to XT60 10AWG Connector for Plug 3 Pin 50A/120A/175A/350A 600V High Current Gray Battery Charging Connector Plug to enhance connectivity.

Wire harness assembly is a process of binding several wires and cables in a particular configuration to ensure that the machines and appliances attached can function properly. This assembly quality is critical because it dictates how well a product will perform. When a wire harness is well made and constructed of strong materials, it ensures the device will receive the proper power and signals without issue. High quality wire harness can prevent the wires from break, short out to the ground or fire. If wires are twisted or improperly connected, devices may cease to function or be destroyed by the connection, a hazard. For instance, in cars or home appliances, if the wire harness is not properly made, the engine can fail or a device stop working without warning. GEN understands this and always ensure their wire harness assemblies are meticulously tested using premium quality components. It helps products last longer and perform better. GEN, a superior wire harness manufacturer When companies purchase high-quality wire harnesses from GEN, they can be confident their products will be safer and more secure. It’s the reason that quality in wire harness assembly is not limited to making wires look pretty; it’s about ensuring that, every time someone uses the finished product, everything on it functions safely and correctly. To support these assemblies, we also provide YQK-70 Hydraulic Plier Steel Integral Hydraulic Crimping Pliers Manufactured in China for precise wire crimping.

Wholesale wire harness assembly is about buying or making a lot of wire harnesses at one time. And it costs less than making few at a time. Manufacturers who buy in bulk from GEN do so at lower prices due to the larger quantity. This is a cost savings, as the investment in materials and labor can be amortized over a large number of pieces. Additionally, GEN utilizes smart machines (in combination with talented humans) to assemble wire harnesses fast and accurately. That means less waste of materials and fewer screw-ups, all of which translates into time and money saved. A second reason why wholesale assembly is cheap is because it keeps down shipping and storage. When many wire harnesses are produced in one batch it is practical and cost-effiective to bundle them together so they can be packed and shipped all at once instead of shipping small orders multiple times. Manufacturers can also save money because they won’t need to purchase parts separately or spend additional time connecting wires themselves. Getting out ahead of the game by buying wholesale from GEN allows businesses to arrange things in advance rather than be hobbled by production stoppages. That way, they can produce more products and sell them sooner, which is good for business. So, wire harnesses wholesale assembly is a wise solution for companies that are trying to save money but still desire good quality parts.

Copyright © Shenzhen Green Power Technology Co., Ltd. All Rights Reserved