Do High Current Electrical Connectors Work? These must be able to carry strong electric currents without overheating or breaking. At GEN, we manufacture these connectors to be rugged and durable because a countless number of machines and systems rely on them daily. As electricity flows through a connector, it encounters resistance that can generate heat and damage. That’s why the material and design are so important. Some folks believe they can use any connector, but for good high current performance the only safe one is the right one. GEN’s cords are heavy-duty and meant to last, even in dire areas like factories or huge machinery where electricity is thick and constant. Consider exploring our Oem Custom Small Stamped Processing Services Brass Aluminum Copper Stainless Steel Hardware Sheet Metal Bending Stamping Parts for robust hardware solutions.

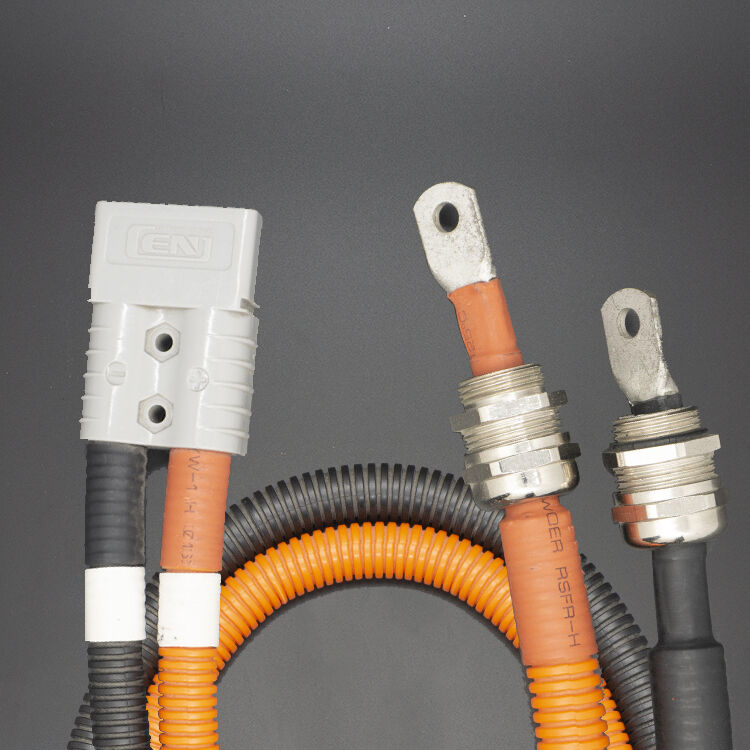

In big machines and heavy work, you will essentially need high current electrical connectors because they can safely carry gigantic amounts of electricity. Think of a big motor or a power generator: If the connector is flimsy or too small, it can melt and fail, breaking down the entire machine. The connectors on GEN’s products are constructed of strong metals that don’t rust or wear so much as thin. They have large surfaces inside to allow electricity to move nicely, and are excellent at stopping heat buildup. By using these connectors in heavy machinery, you prevent the costly and time consuming breakdowns. Also, the machines may work in brutal conditions, say out of doors or amid corrosive chemicals. GEN: You also make connectors that are water-, dirt- and even shock/vibration-resistant. And those things might sound minor, but they can be major issues if not addressed. A connector that isn’t capable of flowing high current could cause a spark or a fire, which can be extremely dangerous. That’s why engineers rely on GEN’s products for big jobs. The last thing you want is a connector that fails when the machine works hard. Another thing is easy installation. GEN offers connectors that fit and stay tight, so electricians don’t waste time resolving loose connections. These connectors will keep everything, no matter how high is the electrical current in a safe position and sound condition. This is Why Heavy-Duty Machines Last Longer, Work Better with GEN connectors. For specific connector models, check out our 50A Andersons to XT60 10AWG Connector for Plug 3 Pin 50A/120A/175A/350A 600V High Current Gray Battery Charging Connector Plug.

High amp electrical connectors share some problems between them that we won’t ignore, these can lead to an issue over time if not taken care of. One big issue is overheating. Connectors can melt or break when they become too hot. This occurs in case the connector is too small or the wires are not correctly attached. GEN always takes care to make sure our connectors are the correct size, and that they can stand up to some heat. Another problem is corrosion. When metal parts come into contact with air and moisture, they eventually start to rust, in turn giving you a bad and unsafe connection. That’s why GEN features special coatings and materials that prevent rust. Sometimes the connectors become loose due to vibration, and sometimes they are simply poorly installed. If a connector is loose, the electricity can’t flow properly, leading to sparks or loss of power. To avoid this, GEN designs have locking parts or screws to keep connectors firmly in place. It also doesn’t help that dirt and dust get into the mix by clumping up in the connection as well. GEN’s connectors are often kept free from dirt by seals or covers. Another problem is wrong matching. And to plug into some cheap shop hardware and blast things with higher current where it fails. Choosing the right connector for your entitySo it's important to pick the right connector for what you're trying to do. At GEN, our staff helps our customers select the best connector for their application so there are no mistakes. Regular cleaning and inspection can prolong the working life of a connector. It’s like maintaining a bike — the cleaner and tighter it is, the better it rides. Same with connectors. To feed that devil is to prevent big trouble down the line. GEN’s experience is that working with care in the design and maintenance of electrical systems keeps them safe and secure. It's not just about the production of connectors, but ensuring they are functional every single day. Learn more about our Durable 2-Pin Connectivity Battery Power Connector 15-45A in the Product Category of Connectors for reliable solutions.

Considerations when selecting high current electrical connectors Quality and cost are an important part of the decision process for choosing a high current connector. Quality is how well the connector performs and how long it lasts. Price is what you have to fork over in order to buy it. Occasionally, lower-cost connectors can feel like a deal, but they may not last as long or operate as effectively. On the other hand, sometimes way overpriced connectors have some features you probably do not need. GEN understands this trade-off and provides connectors that offer high quality at a reasonable price.

The material of which the connector is made is one important factor that determines quality. Well-designed connectors are made from metals that conduct electricity very well, such as copper or special alloys. GEN has used good quality materials in making their connectors thet can withstand significant current without damage. Another thing to consider is how well a connector complements other parts. If it is too loose or does not make a firm connection, it could result in energy loss or sparks. GEN devises connectors that snap and stay locked in place even as cars jostle.

Durability is also important. There are not only heat, humidity of the racing environment, but also connector connection need to bear the vibration when working. If a connector fails and breaks down under the influence of weather or movement, it can lead to the failure of the entire structure. GEN tests their connectors so they are proven to work in harsh environments over a long period of time. Keep in mind the cost when considering price. A connector that is longer-lasting and more effective can save money in the long term by reducing the need for repairs and energy waste. For custom fabrication needs, GEN also offers High Precision Sheet Metal Laser Cutting Punching Steel Welding Bending Aluminum Custom Metal Fabrication.

For instance, in solar power system, when sunlight pounds the solar panels, it produces electricity. This electricity travels through high current connectors into a battery or an inverter, which transforms the electricity into energy that can be used to power homes or businesses. This is where GEN’s high-current connectors come in, as they have enough ability to deal with the strong currents without releasing energy or breaking. They are also resistant to heat and weather, which is important, because solar panels tend to be outdoors exposed continuously to all types of weather. Complement your solar setups with our Factory Custom High Quality Anderson Connector Plug to Solar Connector /crocodile Clip Wiring Harness.

Copyright © Shenzhen Green Power Technology Co., Ltd. All Rights Reserved